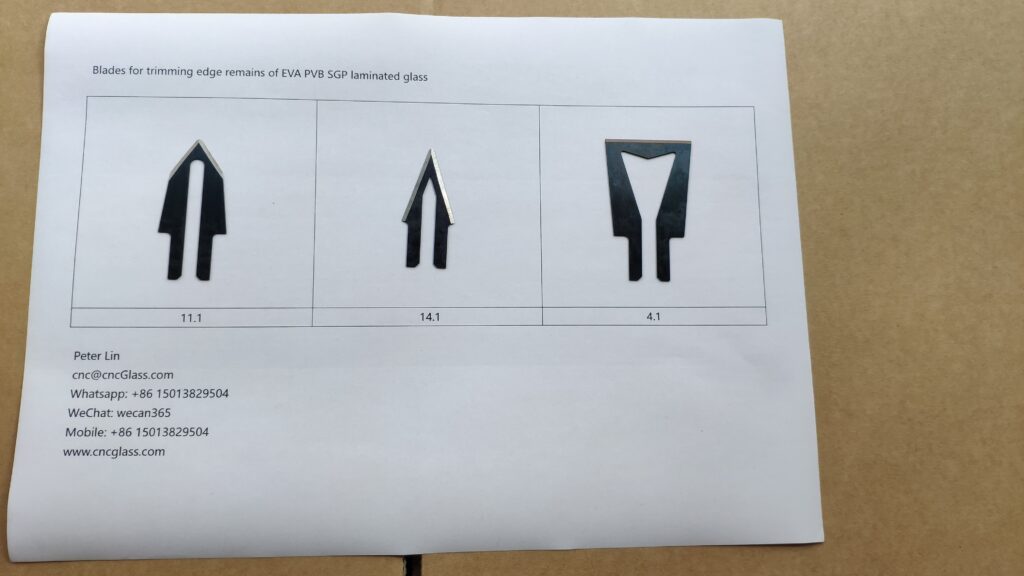

heavy duty hot knife for eva pvb sgp interlayer remains trimming (11)

cnc@cncglass.com

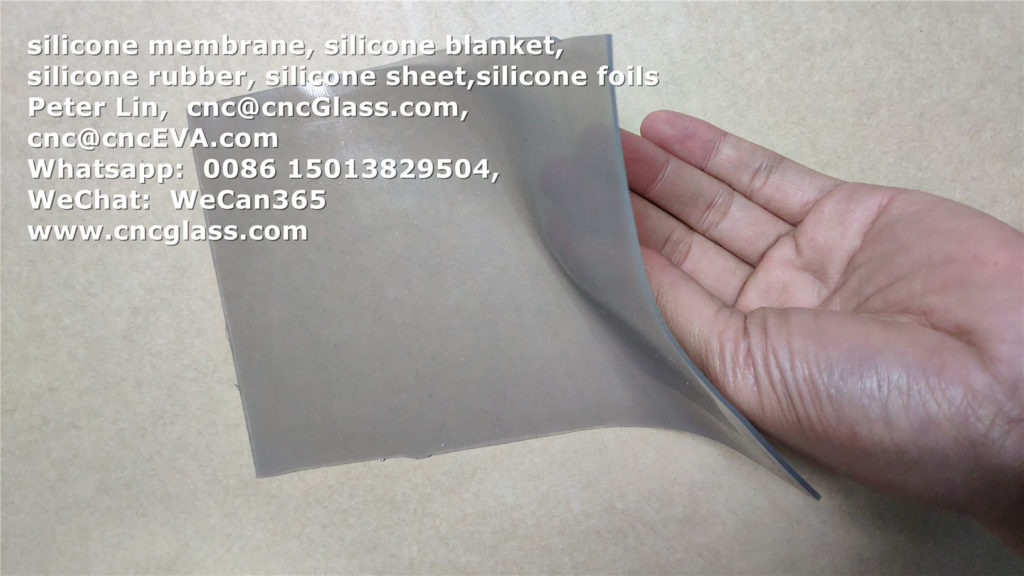

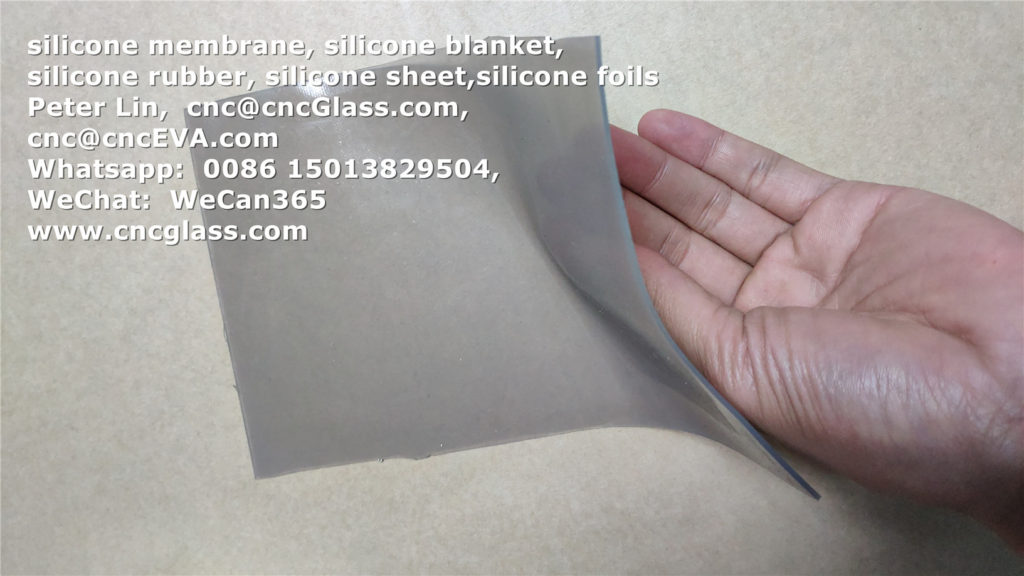

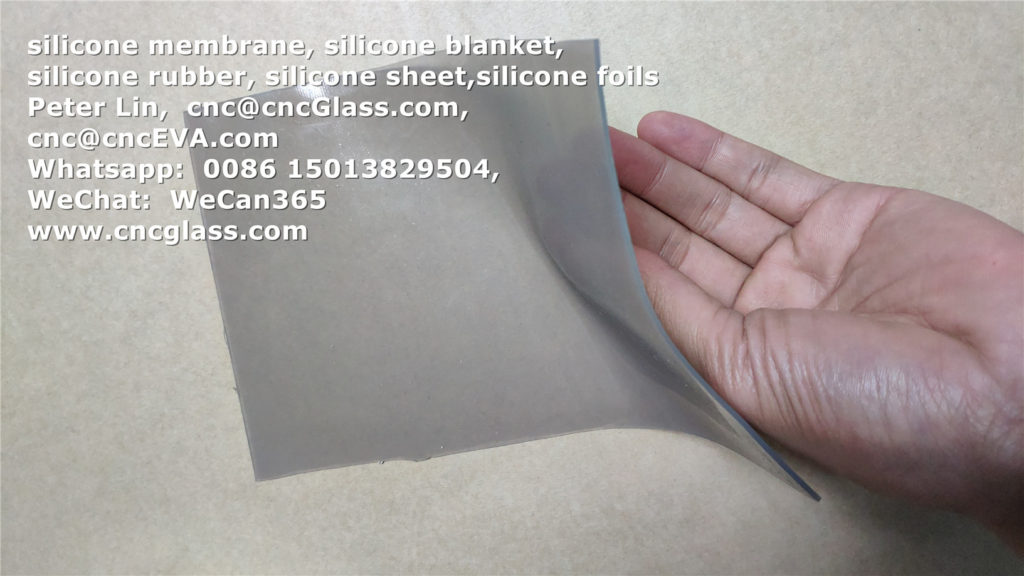

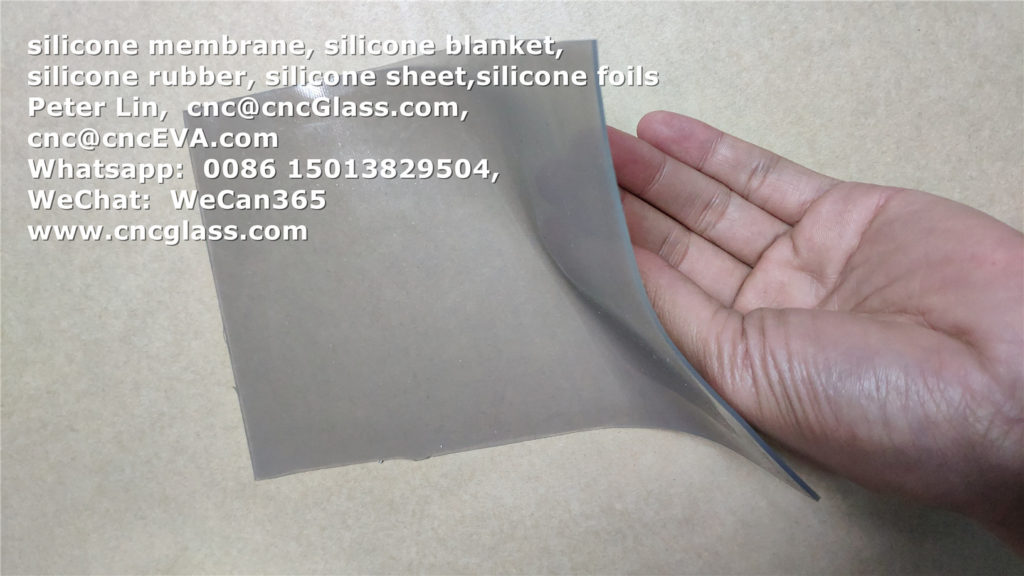

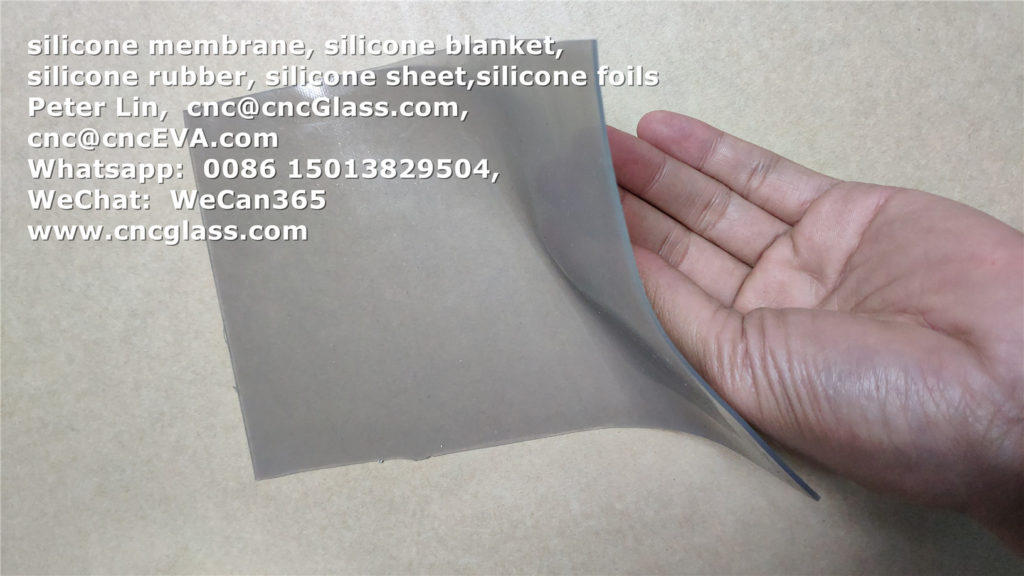

silicone membrane, silicone blanket,

silicone rubber, silicone sheet,silicone foils

Peter Lin, cnc@cncGlass.com,

cnc@cncEVA.com

Whatsapp: 0086 15013829504,

WeChat: WeCan365

www.cncglass.com www.cnceva.com

Wood Silicone Sheet for Wood Door Vacuum Laminating Machine Vacuum Press Machine Vacuum Filming Machine

+Wood Door Vacuum Laminating Machine Press Machine Curtain Coater Machine

1-Two working tables and two independent Vacuum Filming Systems

2-Operate both automatically and manually

-Features of Vacuum Filming Machine:

1-This Vacuum Filming Machine bears two working tables and two independent Vacuum Filming Systems.

2-Vacuum filming can be operated both automatically and manually.

3-The high efficiency, fast finishing, stable laminating, smoothing surface and reasonable structure are its features.

4-The operation and maintenance are simple. The Vacuum Filming Machine is the ideal working equipment for making furniture, cabinets, decorative materials, works of art, advertisements, sound boxes industry.

-Application Range of the Wood Door Vacuum Laminating Machine:

The Wood Door Vacuum Laminating Machine is the suitable for using in the industry of doors, furniture, wooden cabinet, sound box, decorative material, building material, work of arts and advertisement.

+Silicone Sheet for Wood Door Vacuum Laminating Machine Vacuum Press Machine

-Product use: The silicone sheet is for Vacuum Filming Machines(Vacuum Laminating Machine/Vacuum Press Machine)

-Common specifications: 2*1350*2750, 3*1600*3000, Special specifications of silicone sheet can be customized.

-Product features: silicone sheet is produced with advanced techniques and special equipment, large drum-type vulcanization unit , so the silicone sheet owning the high tear-resistant, high level of stability, a good evenness and reliability, and its heat resistant up to 250℃.

-Standard dimensions of Silicone Sheet:

1-common thickness:2mm,3mm

2- maximum width: up to3800mm, without split joint

3-any length

4- common color: grey transparent

5-excellent elasticity

6-longtime flexibility

+UCOLIN SILICONE TECH

(1)-Silicone Vacuuming Bag for EVA Glass Laminating Machine/Privacy Glass Laminating

(2)-Silicone Sheet for EVA Glass Laminating Machine

(3)-Silicone Bag for PVB Glass Laminating Auto-clave

(4)-Silicone Rubber Sheet for Solar Cell Module Laminating Machine

(5)-Silicone Sheet for Wood Door Vacuum Laminating Machine Vacuum Press Machine Vacuum Filming Machine

+ How to Use Wood Door Vacuum Filming Machines(Vacuum Laminating Machine/Vacuum Press Machine) Correctly

1-Before you use Wood Door Vacuum Filming Machines(Vacuum Laminating Machine/Vacuum Press Machine), please check if the machine turning part is all well installed.

2-Clean the table of Wood Door Vacuum Filming Machines(Vacuum Laminating Machine/Vacuum Press Machine)

3-Prepare the materials you need.

4-Adjust temperature and time based on the vacuum filming thickness.

5-If you laminating small pieces together, make sure the distance is long enough for vacuuming.

6-Before starting heat, make sure worker’s hands are off.

7-Don’t let people stand around the machine when machine is working.

8-Don’t put things on heating mantle of Wood Door Vacuum Filming Machines(Vacuum Laminating Machine/Vacuum Press Machine).

9-If machine go wrong, turn off power of Wood Door Vacuum Filming Machines(Vacuum Laminating Machine/Vacuum Press Machine) immediately.

10-Make sure the people who repairs the Wood Door Vacuum Filming Machines(Vacuum Laminating Machine/Vacuum Press Machine) is killed.

All rights reserved by UCOLIN SILICONE TECH

(1)-Silicone Vacuuming Bag for EVA Glass Laminating Machine/Privacy Glass Laminating

(2)-Silicone Sheet for EVA Glass Laminating Machine

(3)-Silicone Bag for PVB Glass Laminating Auto-clave

(4)-Silicone Rubber Sheet for Solar Cell Module Laminating Machine

(5)-Silicone Sheet for Wood Door Vacuum Laminating Machine Vacuum Press Machine Vacuum Filming Machine

We post some inquires form our clients here in order to show you our products are well sold.

But to protect the the privacy of clients, the company or personal info are hidden.

】】】】】】】】】】】】】】

Hi Peter,

My name is ************and I work for**********************Glass in South Wales.

We’ve recently had a Sager Tec Laminator installed with us and been having a few issues with 21.5mm Laminates.

First issue was having bubbles on the edge of the glass behind the tape but not inside the Laminate. We solved this by reading your post on this. Thank you.

I was hoping you could guide me in the right direction with another issues we’ve had.

Let me talk you through it.

The Laminate in question is 2400×1100 2@10mm Clear. We preheat the oven at 70deg for 30mins with the vucuum on the laminate. We then place the laminate inside the oven for 15mins at 70deg then 45mins at 130deg. After the cycle has ended we leave the laminate in for 10mins then pull it out with the vacuum still on for a further 30mins.

Doing this method for smaller pieces is OK but what we found with this is that its leaving a line of small bubbles inside.

I’ve provided a photo showing the bubbles and the pattern.

Hope to hear back from you.

】】】】】】】】】】】】】】】】

【SHOWCASE OF INQUIRIES】

We post some inquires form our clients here in order to show you our products are well sold.

But to protect the the privacy of clients, the company or personal info are hidden.

Peter Lin, cnc@cncGlass.com,

cnc@cncEVA.com

Whatsapp: 0086 15013829504,

WeChat: WeCan365

www.cncglass.com www.cnceva.com

![]() SILICONE SHEET

SILICONE SHEET

SILICONE BLANKET

SILICONE RUBBER

FOR EVA PVB SGP GLASS VACUUMING

Peter Lin, cnc@cncGlass.com,

cnc@cncEVA.com

Whatsapp: 0086 15013829504,

WeChat: WeCan365

www.cncglass.com www.cnceva.com

Silicone rubber sheet for glass industry is a key component of our company dedicated to supporting the glass vacuum laminated furnace according to market demand.

Laminated glass vacuum furnace uses vacuum principle, make the glass heated under vacuum conditions, with the atmospheric pressure, let the glass in the vacuum bag pressed to exclude air and unable to make bubbles, vacuum bag is under heating and vacuum pumped conditions to make two or more pieces of glass and EVA hot together.

Vacuum bag is a core part of glass vacuum laminated furnace, it makes up of two pieces of silicone rubber sheet and silicone sealing edge, silicone rubber sheet is a key component of the entire laminated furnace, its quality directly affects the quality of glass products.